Competence in Sheet metal manufacturing

From steel, stainless steel and aluminum, we manufacture everything that our customers require, from simple laser-cut parts to ready-to-install systems! Bechtold offers future in sheet metal!

Professional sheet metal manufacturing means manual skills and industrial production at the same time, it is both instinctive feeling and robust processes. We maintain cooperation and enhance creativity. From these values new ideas arise to achieve an optimal product at the end: in the appropriate quality, manufactured with the highest precision and delivered on time, at a reasonable price.

For us, every customer and every task, is individual. We commit to high-performance targets from the very beginning. That's why we know our way around sheet metal processing. First and foremost, however, we meet the requirement that our customers demand from us: "Bechtold as a problem solver".

Admissions

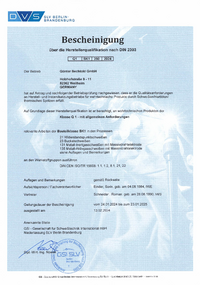

Certified Competence

With our approvals, we ensure your quality standards. Thanks to permanent improvement processes, we are always up to date.

Planned certification DIN EN 1090

We are currently planning the certification according to DIN EN 1090. As soon as we have been certified, we will inform on our website.

DIN ISO 9001:2015

For us, this standardized quality system is much more than just a certificate. The entire company is geared towards this. The many audits of our customers have confirmed this to us. The constant monitoring of delivery reliability and the quality quota are part of our everyday life and allow us to solve difficult and complex tasks on time. We use a modern ERP system to support this. The continuous improvement process (CIP) and the constant training of our employees help us to keep up with the times.

Machine list

Our machine park needs no further comment. Look for yourself:

| Machine | Manufacturer | Number | Size | Specials |

|---|---|---|---|---|

| Laser | Trumpf 6kW | 3 | 1550 x 3000 mm | (Stainless) steel up to 30 mm, Aluminium up to 15 mm |

| Laser/Punching-Combination | Trumpf Fiber | 2 | 1250 x 2500 mm | Nibbling, beading, thread forming, gills, etc. possible |

| Bending | Trumpf | 5 | Bending length up to 3000 mm | from 35 to 230 tons pressure |

| Deburring | Weber | 1 | up to 20 mm | Continuous deburring, descaling and grinding of steel |

| Deburring | Weber | 1 | up to 20 mm | Continuous deburring of stainless steel and aluminium |

| Welding robot | Cloos | 1 | 2 x 1 x 1 m³ | 3D-Welding, TIG and MIG/MAG |

| Welding | Lorch | 10 | MIG/MAG, TIG of steel, stainless steel and aluminium | |

| Spot welding | Dalex | 4 | 4 mm steel on 4 mm steel | Steel and stainless steel up to 4 mm, Aluminium up to 2,5 mm |

| CNC stud welding | Soyer | 5 | up to 20 mm | Point- and draw ignition |

| PEM Serter | PEM | 2 | Insert studs, nuts, etc. | |

| Laser engraving | Trotec SpeedMarker 1300 | 1 | 1000 x 700 mm |

(Last update: July 2020)

Prospect

Our next goals

Our high technical standard and modern production are an obligation for the future. We are systematically developing our production today and in the following years.

Logistical systems, which are already a matter of course today, are being further expanded and digitized in order to be able to offer our customers a tailor-made delivery system according to their wishes. Another goal is to further develop automation, which we have already started with a fully automatic punch-laser center. Further (partially) automated solutions will follow in the next few years.

Environment

Sustainable manufacturing and environmental protection have become an important corporate goal. We produce 50% of our annual electricity consumption with our own solar system, the rest we buy as green electricity from the grid. Since 2018, we have been able to reduce the electricity requirements for lighting by LED lighting technology by 75%. 80% of our waste is recycled and thus returned to the economic cycle. Our buildings are efficiently insulated and are heated in a resource-saving manner using a combination of natural gas and electric heat pumps.

By replacing our machines with the latest generation (especially fiber lasers), we will be able to significantly reduce our energy consumption in the coming years. For business trips, we use the train wherever possible, which is important to us as a supplier in this area. The proportion of electric vehicles in the fleet is now 50%. We support the "Green Deal” of the EU Commission and support the goal of our federal government to be carbon neutral by 2050.