Our procedures

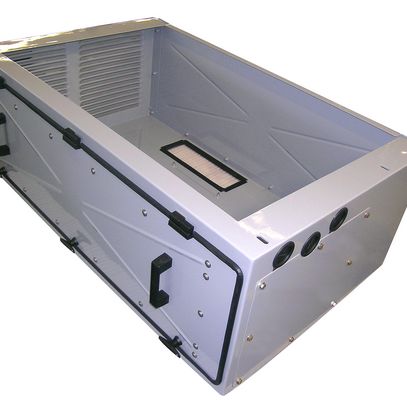

The manufacturing process is strictly based on the material flow. Everything that has to do directly with sheet metal and sheet metal production is in-house. This includes the classic procedures such as:

But also:

Spot welding | Stud welding | Rivets | Press in | Assembly | Rounding | Setting | Grinding | Reshaping

Materials

We manufacture with a wide variety of materials. We have most of them in stock so that we can react quickly and flexible to your requirements. To be edited:

- Non-ferrous metals such as copper, brass or titanium in different material thicknesses for a wide product portfolio.

- Stainless steels from 0.5mm to 20mm (30 mm) in common qualities such as 1.4301 (V2A), 1.4571 (V4A), but also high-temperature steels or special steels.

- Aluminum from 0.5 mm (0.3 mm) to 15 mm (20 mm), not only AlMg3 and Al99.5, but also special alloys with surfaces such as mirror finish.

- Steel from 0.5 mm to 20 mm (30 mm) in a wide variety of qualities such as DC01, DD11, S235, S355, S700mc, Raex, Domex, etc. Likewise coated sheet metal from Zinkor to powder coating or gold plating.

Complementary procedure

With certified and long-term partners, we supplement our process chain to meet all your requirements.

The focus is on surface processing such as powder coating, wet paint, Kepla-Coat, polishing, grinding or all galvanic coatings.

Machining of all kinds – from the simple welding chamfer to the complex milled or turned part – are integrated into the own production process.

Assemblies from the smallest diode to insulation material to the large, worldwide used designer lamp are just as much part of our daily routine as completing and picking various assemblies.

Quality through training

As a long-standing and recognized training company, we secure a constant base of qualified employees.

You can find our current job offers on our careers page.